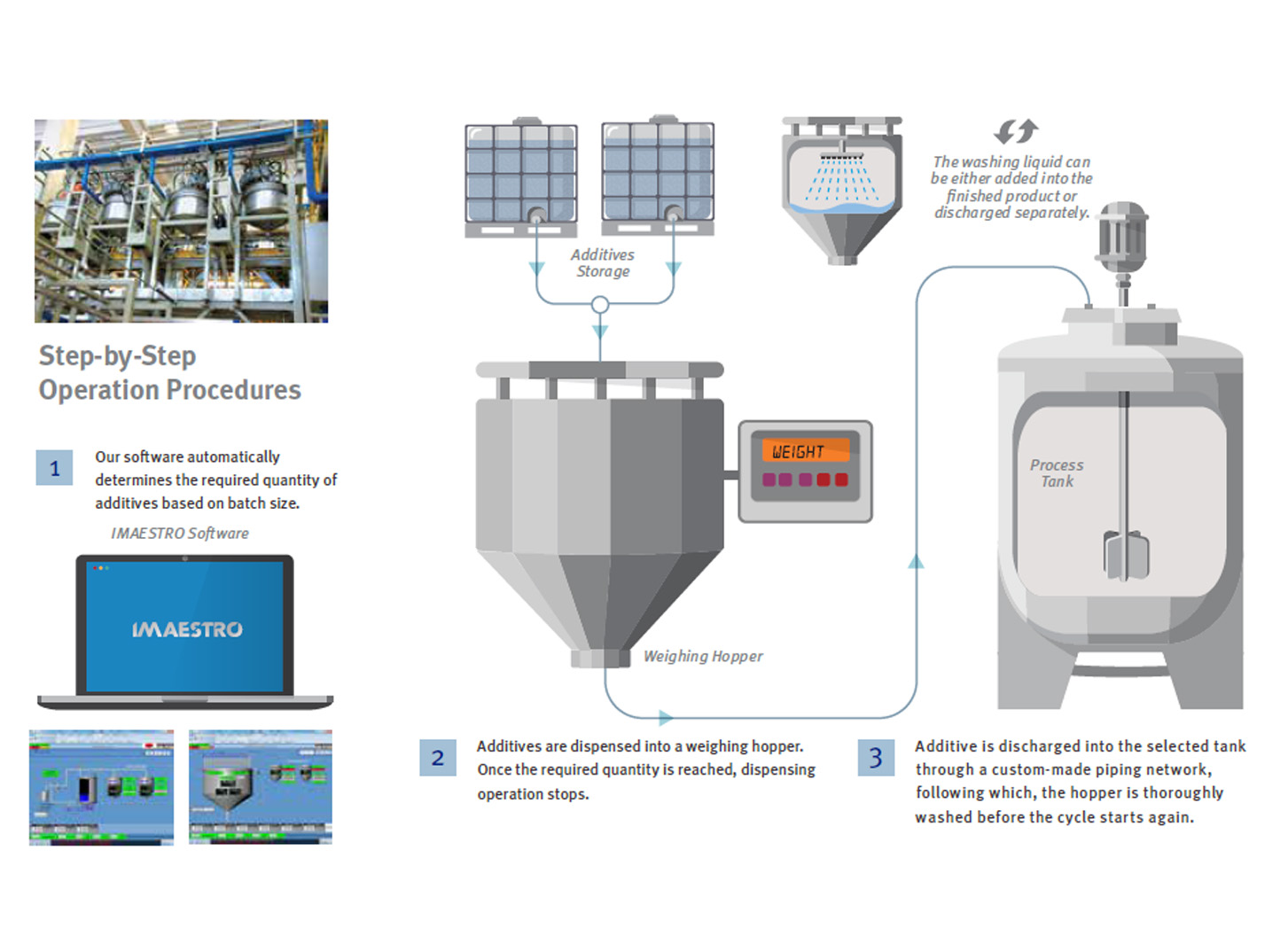

ADDIDOSE: Precise, Reliable, and Automated Additive Dosing for Coatings and Chemicals

Achieving precise additive dosing while maintaining consistent coating quality is often complex.

ADDIDOSE ensures exact measurement and controlled delivery, reducing errors, lowering production costs, and guaranteeing uniform final products.

The ADDIDOSE System

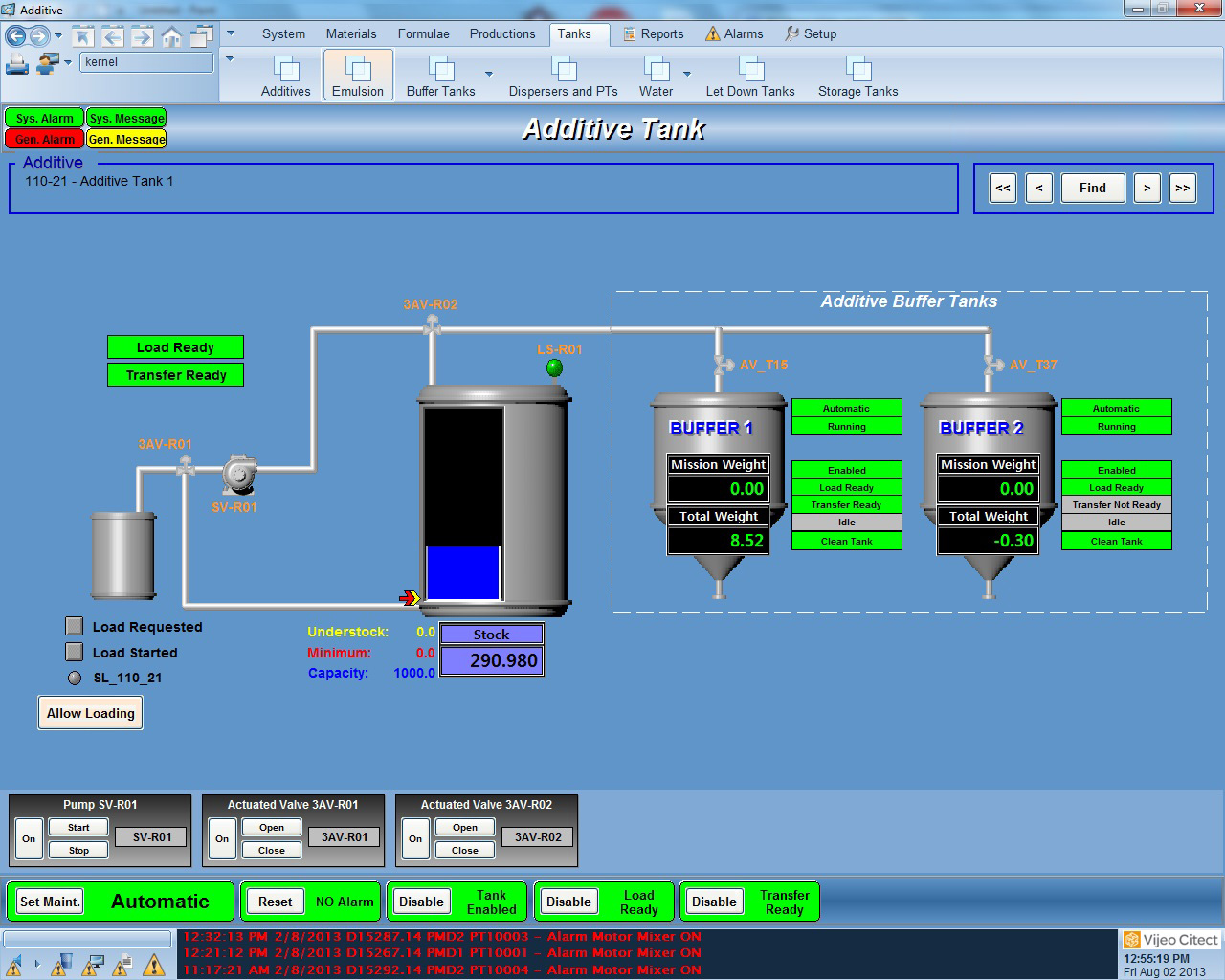

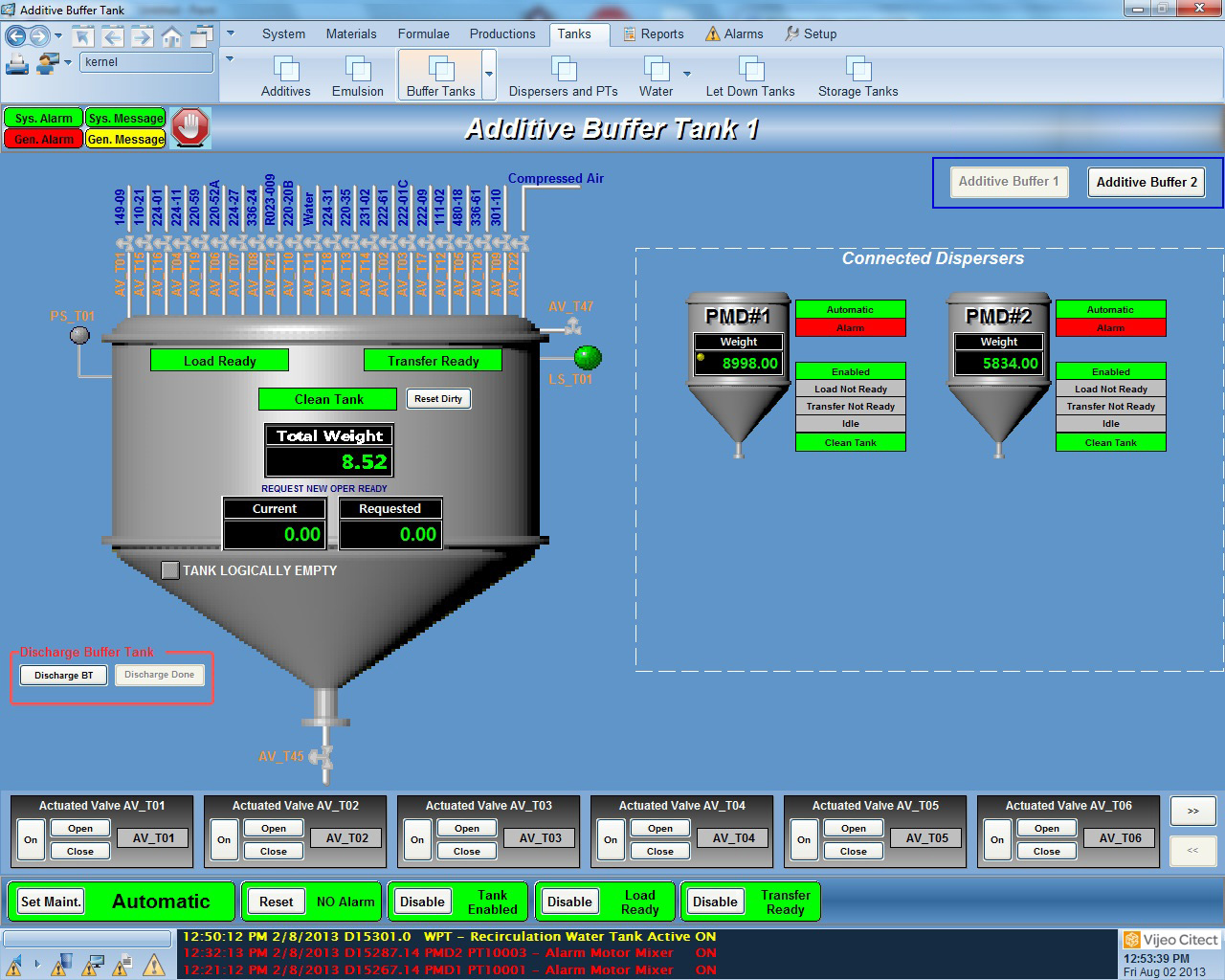

An advanced, software-controlled automatic additive dosing system for industrial coatings, paints, and chemical production. ADDIDOSE stores additives in dedicated containers and transfers them to stainless-steel hoppers with electronic scales. Once accurately measured, additives are delivered through a tailor-made distribution network directly to process tanks, ensuring maximum efficiency, repeatability, and process reliability.

Customised for every production need

The system can be fully tailored to each customer’s requirements, including:

- Dedicated additive storage containers

- Stainless-steel hoppers with electronic scales

- Tailor-made delivery network to process tanks

- Full software control for precise measurement, dosing, and process monitoring

Fast ROI, guaranteed

Powered by IMAESTRO, our industry-leading software, ADDIDOSE maximises safety, repeatability, and traceability, optimises workforce efficiency, and delivers a fast return on investment.