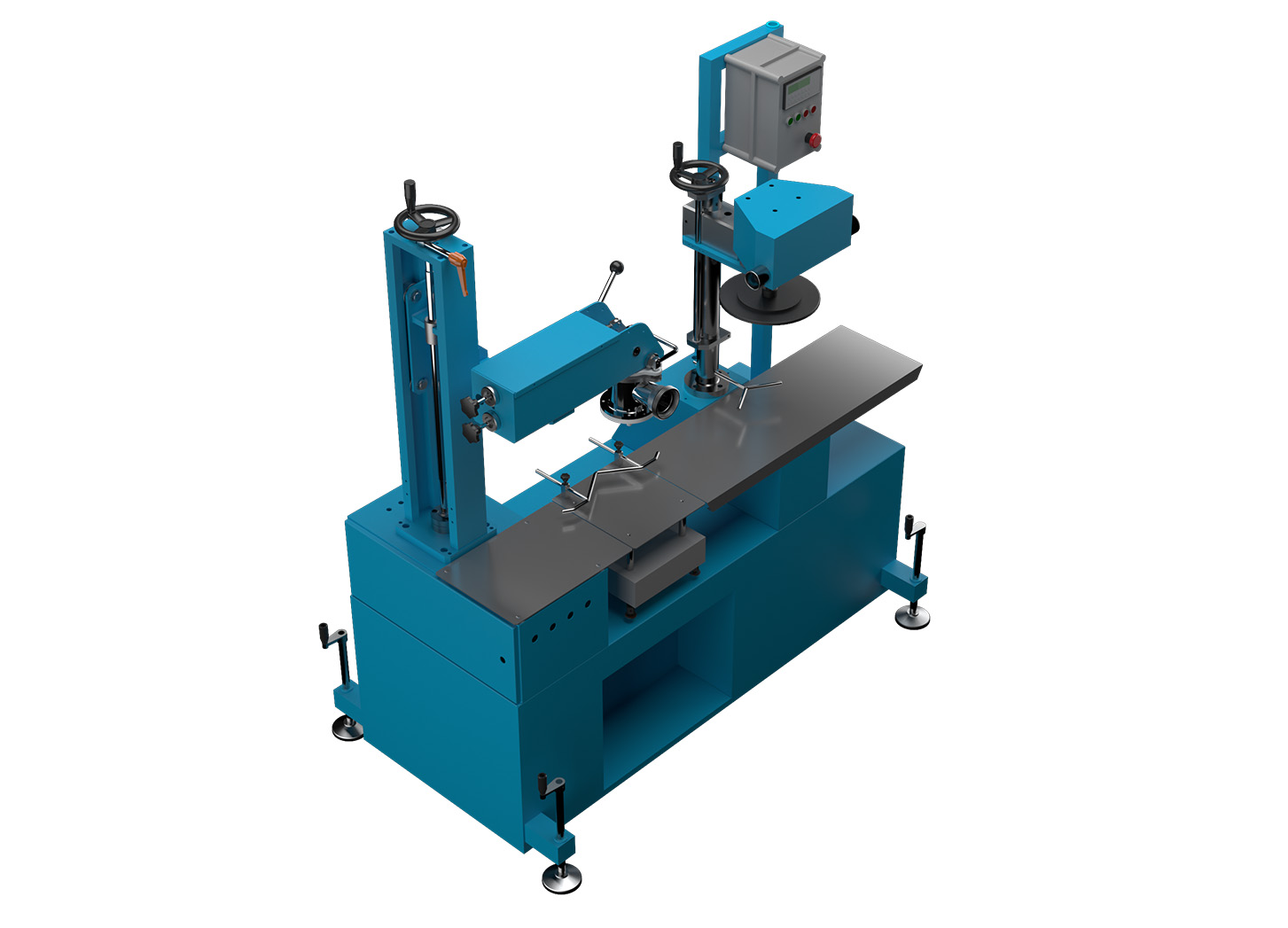

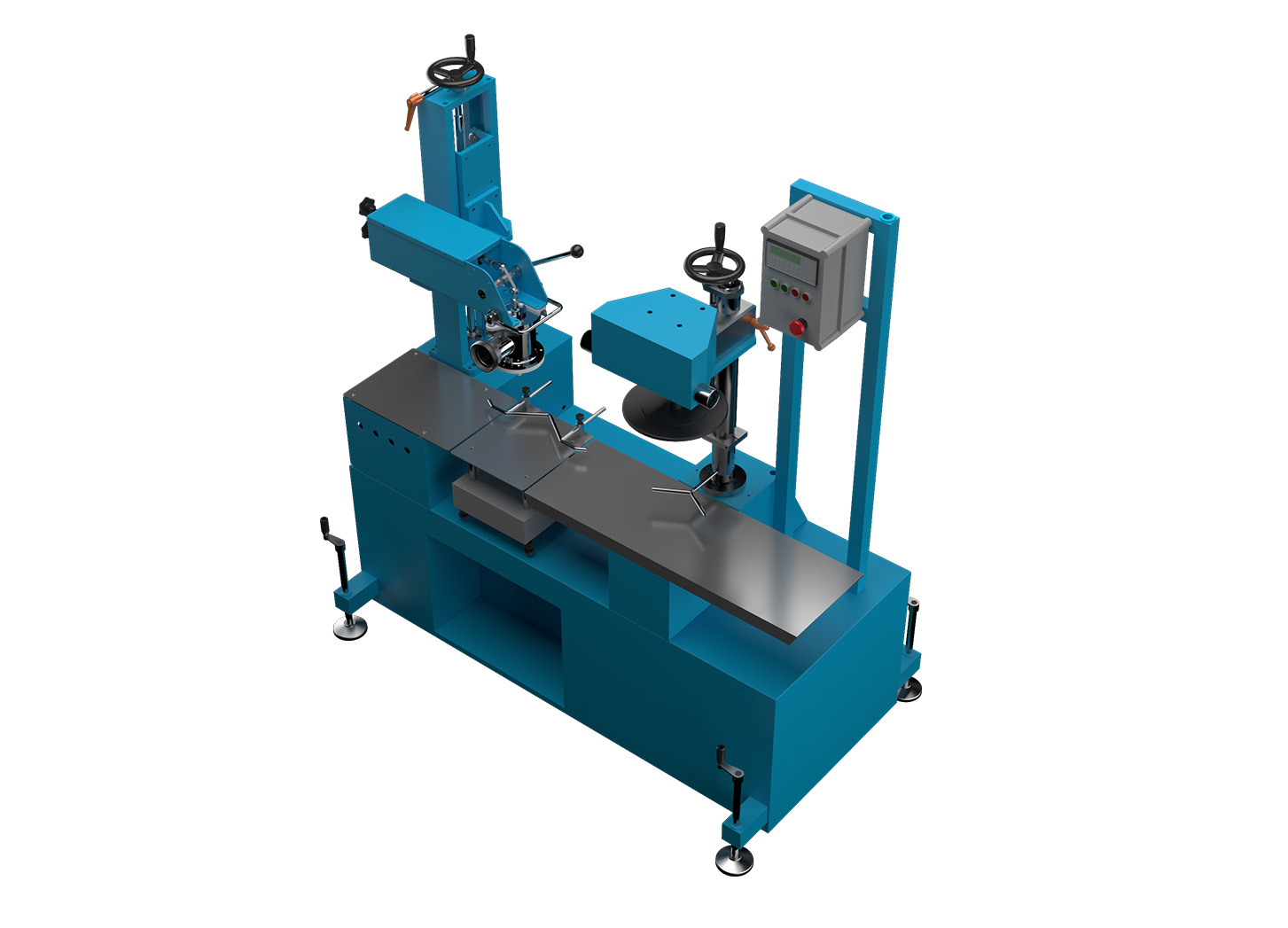

Manual Filling Machine

Design Features

- “First step” filling machine suitable for “small format”

- Dosing valve is easily removed for cleaning

- Manual handling of pails and lids

- Pail-handling on a stainless steel working table

- Electronic scale P6 or Volumetric dosing V5

- Electronic scale capacity 0-30 kg, 10g resolution

- Large storage capacity, up to 63 different weights and relative tares of pails

- Dosing range: from 0.2kg to 3 kg

- Electro-pneumatic control

- Safety devices in compliance with the European Machinery Directive (CE)