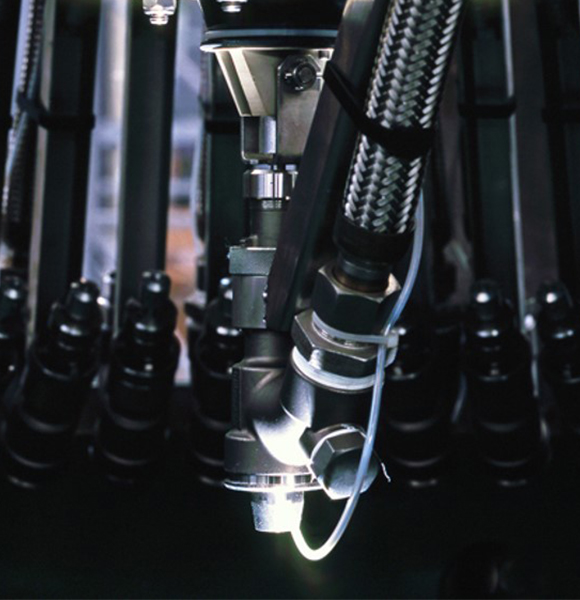

Dispensing Solutions

Dispensing Concept | Rationale

Without Dispenser

Final products are purchased ready made – OR -

Some base ingredients are manually mixed

Inflexible production planning

Inaccurate operation requiring multiple QCs

Time-consuming, labour intensive preparation

Purchase of excessive amount of finished products from the supplier

Poor handling of left-overs leading to wastages

Very poor production traceability

With Dispenser

Accurate formula reproduction with higher consistency & reproducibility

Minimized risk of errors, elimination of over-makes & unnecessary QCs

“Right 1st time” & “Just-in-time, just-enough” concepts: the products you need, only when you need them

Waste elimination: all left-overs are used for future productions

Production flexibility & response time

Stock rationalization

Strict control over costs

Reduced dependability on manpower

Reduction in preparation time

Improved working conditions, safety & hygiene

Better floor space utilisation

Increased environmental protection

Possibility to connect to any brand of spectrophotometer or ERP and to create a fully Computer Automated Manufacturing (CIM-CAM)

Full products management & production traceability according to ISO rules