POS TINTING, COLORING AND DISPENSING TECHNOLOGY

Accuracy and repeatability are two of the most sought after characteristics when it comes to point of service (POS) tinting, coloring and dispensing technologies.

Whether it's the tints and colorants that give the paint the exact shade desired, or the equipment that dispense them into the paint can, paint manufacturers need to be confident that their customers are walking away with the exact color they selected.

Manufacturers of POS dispensing equipment, tints and colorants understand that their technologies play a key role in satisfying customers' needs.

"Our systems are an integral part of our customers' manufacturing process and as such our units need to be, above all, accurate, but they also must be reliable to deliver results day in and day out," said Martin Black, director of sales, Rexson Systems.

Users of POS equipment and technology are looking for durable, user-friendly equipment that offers maximum repeatability and high accuracy of dispensation, according to Edel, a manufacturer of tinting machines, gyroscopic mixers and software.

POS colorants are also held to the same exacting scrutiny as the equipment that dispenses them into the paint formulation. Customers need to be confident that colors will be consistent time and again.

"Customers are looking for consistency in weight per gallon and viscosity so that colorant is dispensed reliably and repeatable from whatever equipment is being utilized," said Roland J. Valin, global sales and technical marketing, color pigments, Engelhard Corp. "Of growing importance is the ease with which the colorants come out of the containers and the minimization of residual colorant. Economics and environmental stewardship are critical issues for our customers."

According to Monique Duits, marketing manager of Ralston Colour Systems B.V., customers are looking for POS tinting systems that are easy to use and companies that offer personal technical support. "It is of mutual interest to operate as a team with our customers," she said "Their success is our success. Therefore, we are willing to share our technical know-how with our customers."

Environmental compliance

A primary concern of users of POS colorants is environmental compliance, however these formulations must still be able to deliver superior performance.

"In Europe, formulators are looking for no-VOC, APE-free and preferably labeling-free universal colorants with excellent storage stability and pumpability," said Richard Meijer, business development manager, colorants Europe for Elementis Specialties. "Although realizing that these colorants are VOC-free, according to European VOC definitions, most customers typically still want to use these colorants in their existing solvent alkyd lines in order to avoid a separate line for alkyds. That's why the no-VOC colorants must still be compatible in solvent-based alkyds. In addition to superior color compatibility, acceptable colorants cannot detract from coatings properties such as gloss and resistance to blocking and water spotting."

Meeting these environmental challenges has been a top priority for Elementis. "Our challenge is to develop a glycol-free colorant, mainly intended for water-based coatings, but still formulated in such a way that they are compatible in solvent deco paints and to do that in such a way that other paint properties including gloss, blocking, hardness and water spot are not significantly affected," said Meijer.

Although the VOC of POS colorants is not an issue in the U.S., the VOC requirements for architectural coatings pose a challenge for manufacturers. "Several coatings manufacturers have ceased manufacture or sale of these items," said Michael Frantz, business development manager, colorants North America, Elementis Specialties. "Those manufacturers are interested in the possibility of water only POS colorant systems that have reduced surfactant levels for better physical properties and reduce viscosity loss on tinting," he said.

To meet these changing needs, Elementis Specialties offers a universal, glycol-free, APE-free and labeling-free universal POS tinting system for architectural coatings in Europe and Asia Pacific called Tint-Ayd WCH Plus. "This is a glycol-free and resin-free technology," said Meijer. Special humectant technology is used in the colorants to ensure good pumpability in tinting machines and prevent too quick drying-out of the colorants. Tint-Ayd WCH Plus system can be used for water-based architectural as well as solvent-based architectural coatings, mainly alkyds.

While Engelhard is developing colorants with either low levels of VOC or no VOC to meet the environmental requirements of the future, the firm continues to improve the lot-to-lot consistency of its colorants for weight per gallon and viscosity as well as color and strength, resulting in better tinting at POS, according to Valin.

When lowering VOCs, there are issues paint makers need to confront. "As colorant lines move toward lower VOC and low or no glycol, drying out of the colorant in the tinting machine is becoming a more crucial issue," said Frantz of Elementis.

"Elementis has developed a special humectant (PEG-free) that is used in these colorants. PEG (PEG 300 or PEG 400) tends to affect blocking and gloss and water sensitivity. When using this special humectant technology, the described problems with PEG can be overcome," he said.

Elementis is developing a new colorant system for North America that will have global applicability. "It will be a modular system that will allow it to be tailored to the client's specific needs, from conventional glycol-based for maximum range of compatibility, to APE-free, zero VOC for compliance with any environmental regulations, to water-only for optimum exterior performance in waterborne coatings. All versions of this system will be formulated to reduce or eliminate viscosity loss on tinting," Frantz said.

CPS Color has developed a universal colorant system for tinting waterborne industrial coatings. The Temacolor W industrial colorant system can be used in a wide range of waterborne coatings, including 2K PUR, 2K epoxy, acrylate, polyester, waterborne alkyds and waterborne decorative paints. The coatings are APE-free and contain the lowest possible amount of VOC. Temacolor W meets the high demands that industrial coatings are faced with regarding color acceptance, gloss and hardness, according to the company.

Ralston's Duits said the company recently launched its Inspiration color cards. "Colors change, customers' choices change and as a result suppliers of tinting systems should also be aware of changing trends," she said. Ralston's Inspiration color cards consist of approximately 1,500 interior and exterior colors.

On the machinery and equipment side, Edel has developed Painter 4.1, a new software management system. Painter 4.1 software has a graphic interface designed to make the most commonly used procedures easier to operate. It can be used in combination with manual or automatic machines. Its main features include a graphic guided search, the ability to create and store numerous formulations and it can be searched by code or name, according to Edel.

Keep it simple

When it comes to developing new POS tinting and colorant technologies, it is best to heed the wisdom of the adage, keep it simple. The easier the technology is to use, the less room for costly user error.

However, there are many factors to contend with when dealing with POS tinting and coloring. According to Valin, dealing with the different types of equipment, maintenance, the store environment, appropriate inventory handling and color consistency all contribute to the success of the colorant dispensing process.

As POS equipment becomes more sophisticated, this represents a great challenge for manufacturers which must utilize the latest technology to develop innovative products, but at the same time keep the products user friendly.

"The challenge is getting ever more powerful and comprehensive software to be user friendly," said Black of Rexson. He said that Rexson's current software matches most of that criteria, and the firm plans to launch a new operator console that makes operating the system as easy and intuitive as the ubiquitous automated teller machine, or ATM, used in the banking industry. "Rexson has invested heavily in R&D and our current range of machines have much fewer parts than previous models," Black said. "The fewer the parts, the fewer things to go wrong. Obviously this 'part reduction' program must maintain or improve the accuracy and repeatability of the units, which is the case."

Rexson like all companies in the industry for the long haul plans to continue to invest in developing innovative machines and software. "The machines will become smaller, more reliable and more accurate, while being easy to use," Black said. "Standing still isn't an option."

EDITOR NOTES

Silvio Cimenti – Global Director of Branding and Marcom, IM GROUP

scimenti@im-group.com

im-group.com

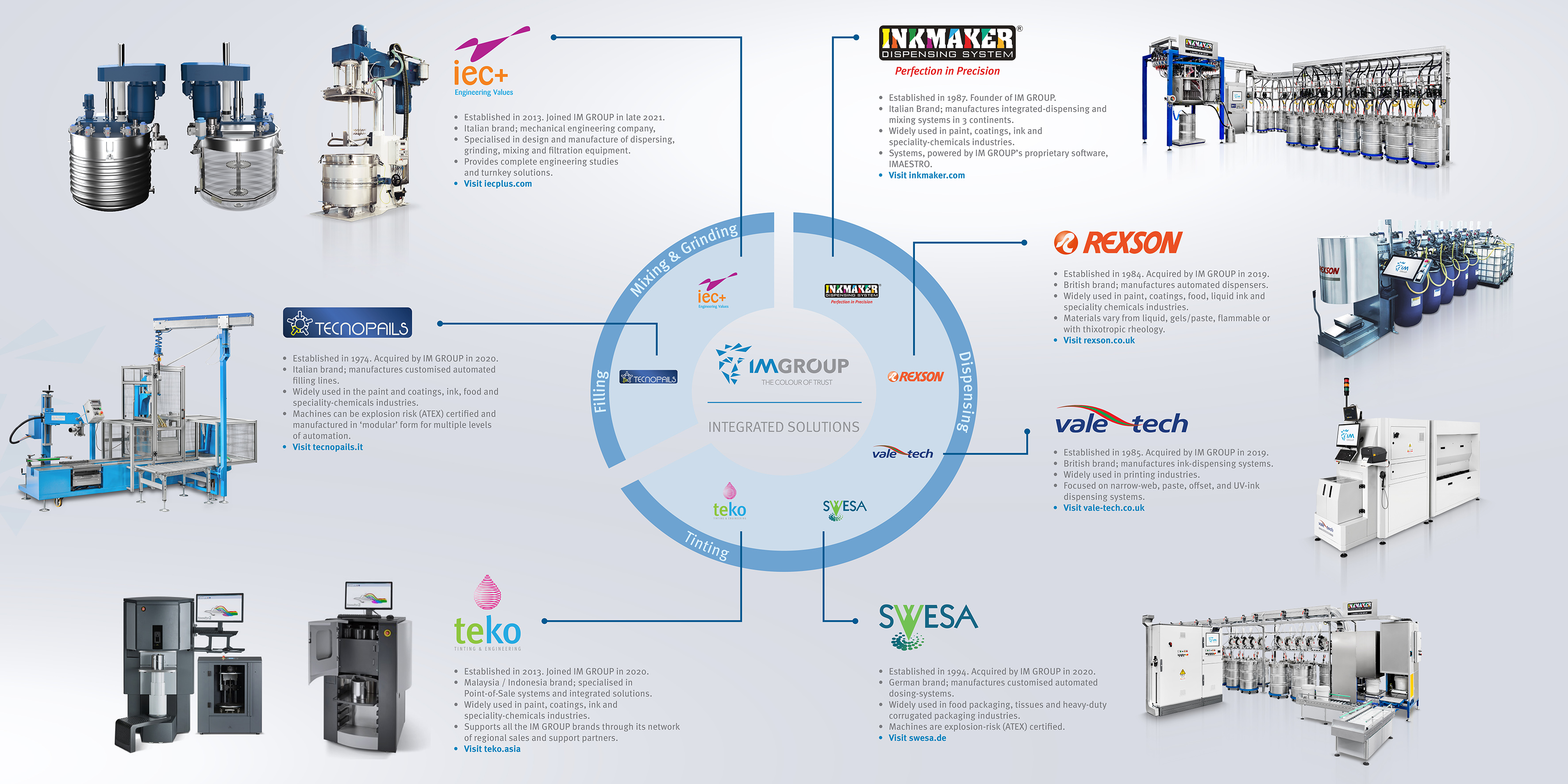

About IM GROUP

Founded in Turin, Italy, on 22 April 2021, IM GROUP is a global leader in technology and integrated engineering solutions, uniting the expertise of its brands; Inkmaker, Rexson, Vale-tech, Swesa, Teko, Tecnopails, and IEC+. The group delivers comprehensive engineering solutions through its two divisions: the Dispensing and Tinting Division and the Filling, Mixing, and Grinding Division, serving diverse industries such as paint, coatings, ink, chemicals, adhesives, pharmaceuticals, and cosmetics. With a presence in 15 countries across five continents, IM GROUP is a trusted partner to Fortune 500 companies, including Boeing, Sherwin Williams, PPG, Akzo Nobel, Avery Denison, International Paper, and Tetra Pak.

To learn more about IM GROUP and its innovative solutions, visit: im-group.com or contact us at IM GROUP

Follow us on LinkedIn.

INKMAKER RECOGNISED AT OFFICIAL OPENING OF DIC’S NEW INK MANUFACTURING FACILITY

Oct 23 2025