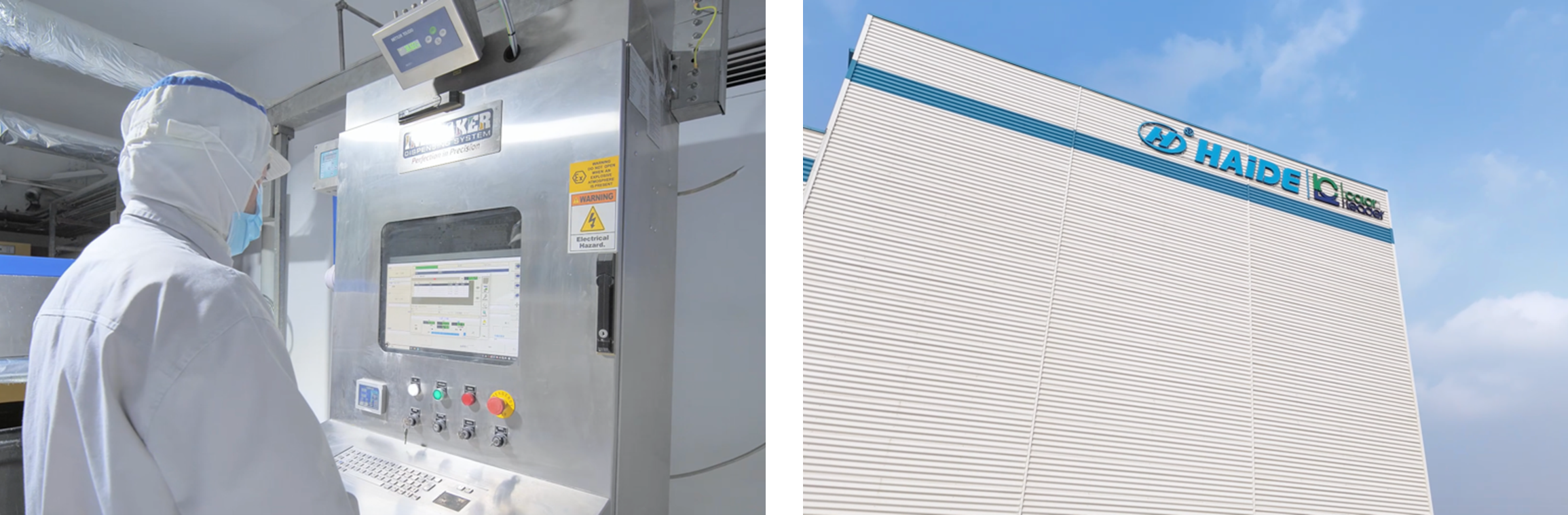

Shanghai, China, 21 Jan, 2025 2025 — Inkmaker Shanghai, a member of IM GROUP, proudly announces the transformative impact of its advanced automatic ink-dispensing system at Qingdao Haide Packaging Co., Ltd. in Qingdao, China, This deployment marks another significant step in revolutionising the flexible packaging industry with intelligent automation solutions.

Qingdao Haide Packaging Co., Ltd, a leading manufacturer in flexible packaging, is known for its commitment to innovation and high-quality production standards. Facing the challenges of conventional colour-mixing methods—such as extended ink preparation times, inconsistencies in colour matching, and substantial ink waste—the company sought a solution to enhance productivity and quality control.

Since implementing Inkmaker’s automatic dispensing system, Qingdao Haide Packaging has achieved remarkable improvements:

- Efficiency Gains: Production efficiency increased by nearly 30%, with ink-mixing times per order reduced by approximately 20 minutes.

- Enhanced Precision: Advanced algorithms ensure that colour consistency reaches ΔE ≤ 1 within a single correction cycle, significantly boosting both colour-matching speed and accuracy.

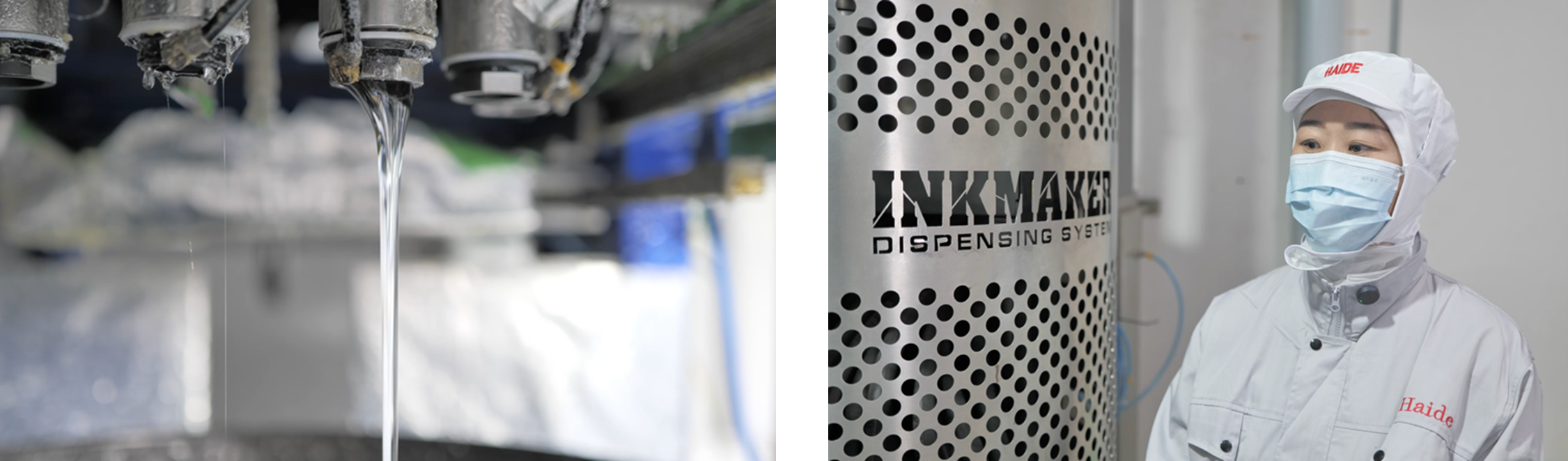

- Cost Reduction: The Inkmaker Automated Ink Management System optimises ink usage, dramatically reducing residual ink waste. Recent data shows that over 50% of previously accumulated residual ink inventory has been utilised effectively.

- Mismatching Reduction: The INKMAKER glue-dispensing system significantly reduces mismatching and manual labour demands.

- VOC Emissions Reduction: Sealed pipeline transportation lowers VOC emissions, improving safety and minimising environmental impact during the glue-dispensing process.

Mr. Liu, Production Manager at Qingdao Haide Packaging, praised the Inkmaker system, stating: "The integration of this technology has significantly enhanced our operational workflow. Our production efficiency has increased by nearly 30%, the average ink-mixing time per ink is approximately 20 minutes faster, and human errors have greatly reduced.

Customer satisfaction with our products has also significantly improved because of the ability to store and retrieve colour data within the system. This means we can read the data directly for future reproductions, ensuring rapid and consistent ink blending, which improves both the production process and turnaround times."

The intelligent features of the Inkmaker dispensing system also extend to sustainable ink management. Automated monitoring allows maximum reuse of residual ink, reducing waste and supporting more sustainable production practices.

Ms. Zhang, Workshop Foreman at Qingdao Haide Packaging, noted: "Tasks that once took hours are now completed in minutes. The streamlined process and improved accuracy have redefined our approach to colour management."

Additionally, the Inkmaker Automatic Glue Dispensing System has completely transformed Qingdao Haide Packaging’s traditional manual gluing production methods. It ensures consistent glue quality, significantly improves safety, and enhances environmental protection by reducing VOC emissions.

Inkmaker’s Automated Ink Management System continues to lead the industry by providing innovative dispensing solutions that integrate automation, digitalisation, and smart technology. As global demand for sustainable, efficient production grows, Inkmaker remains committed to delivering tailored solutions that maximise efficiency and minimise environmental impact.

For more information, please Contact Us

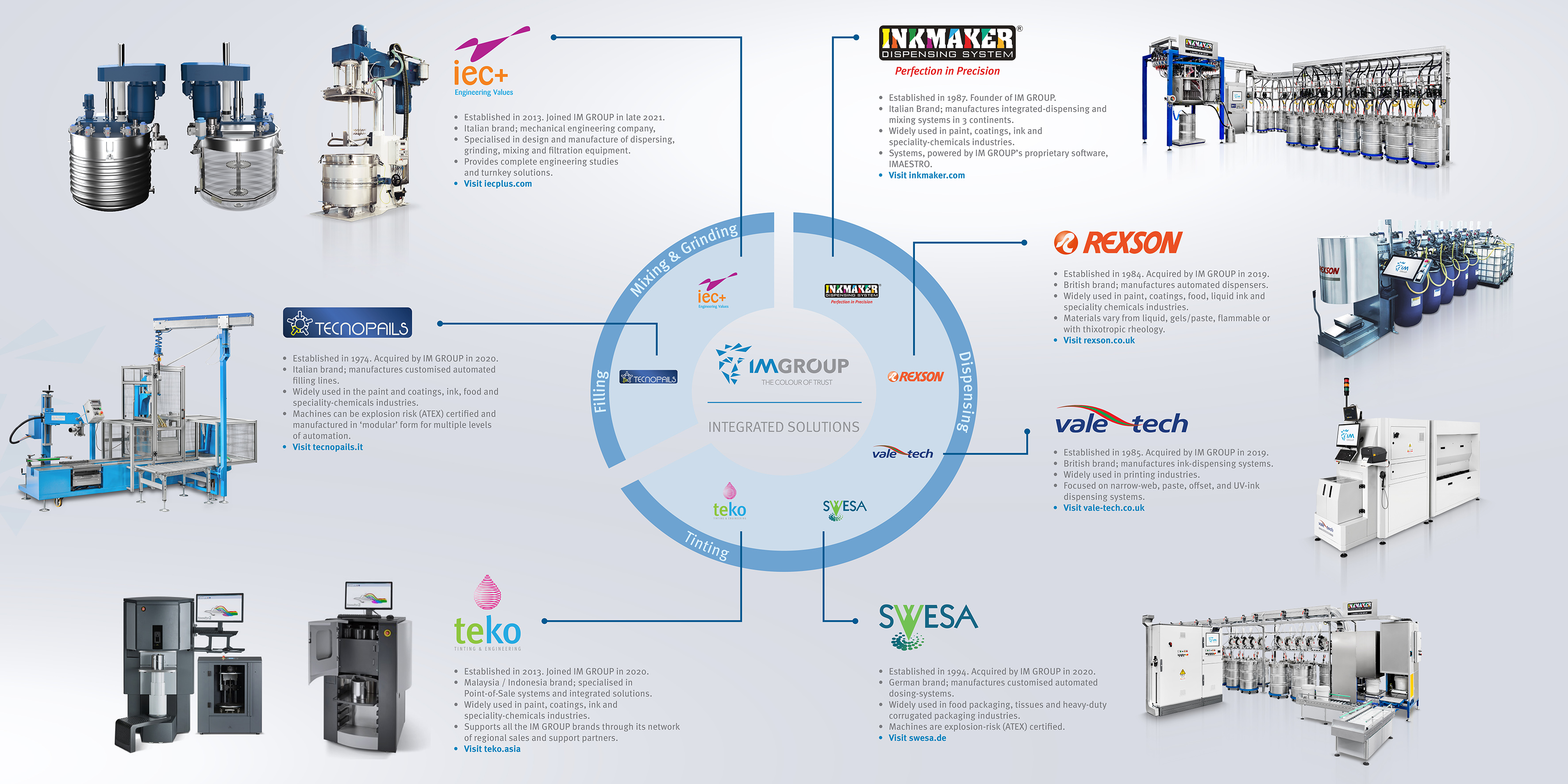

About Inkmaker Worldwide

Inkmaker, is the founder of IM GROUP. Established in Turin, Italy in 1987, it is a global manufacturer of integrated dispensing systems designed to improve efficiency by automating the dispensing and mixing of inks, paints, and chemicals. Inkmaker’s proprietary software and systems, manufactured across three continents, ensure consistently accurate colours, delivered precisely and instantly. Inkmaker operates with its own teams and offices in over 15 countries across 5 continents. Visit Inkmaker.com.

For further information on IM GROUP, visit:

About IM GROUP

Founded in Turin, Italy, on 22 April 2021, IM GROUP is a global leader in technology and integrated engineering solutions, uniting the expertise of its brands; Inkmaker, Rexson, Vale-tech, Swesa, Teko, Tecnopails, and IEC+. The group delivers comprehensive engineering solutions through its two divisions: the Dispensing and Tinting Division and the Filling, Mixing, and Grinding Division, serving diverse industries such as paint, coatings, ink, chemicals, adhesives, pharmaceuticals, and cosmetics. With a presence in 15 countries across five continents, IM GROUP is a trusted partner to Fortune 500 companies, including Boeing, Sherwin Williams, PPG, Akzo Nobel, Avery Denison, International Paper, and Tetra Pak.

To learn more about IM GROUP and its innovative solutions, contact us at IM GROUP

Follow us on LinkedIn

Published in the following Media:

_IEC.png)

INKMAKER RECOGNISED AT OFFICIAL OPENING OF DIC’S NEW INK MANUFACTURING FACILITY

Oct 23 2025